Chrome

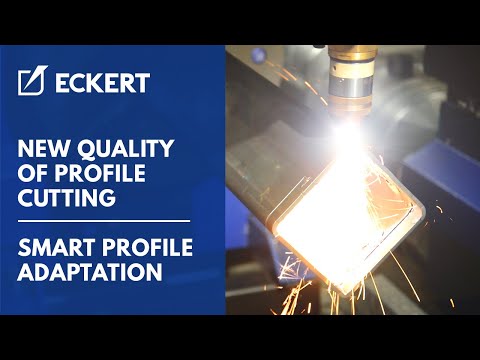

Explore new generation of dynamics and precision in CNC plasma cutting.

Plasma

Oxygen

Chrome

Explore new generation of dynamics and precision in CNC plasma cutting.

Plasma

Oxygen

.jpg?w=210&h=210&f=crop)